When to Use an Expansion Joint Instead of a Hose

Some applications lend themselves to either a metal hose or to an expansion joint, but more often than not, there is a preferred option. A few key application criteria will let us know when to use an expansion joint instead of a hose.

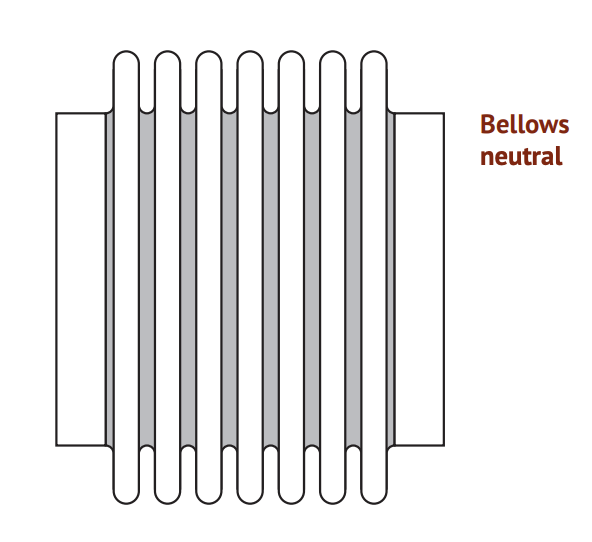

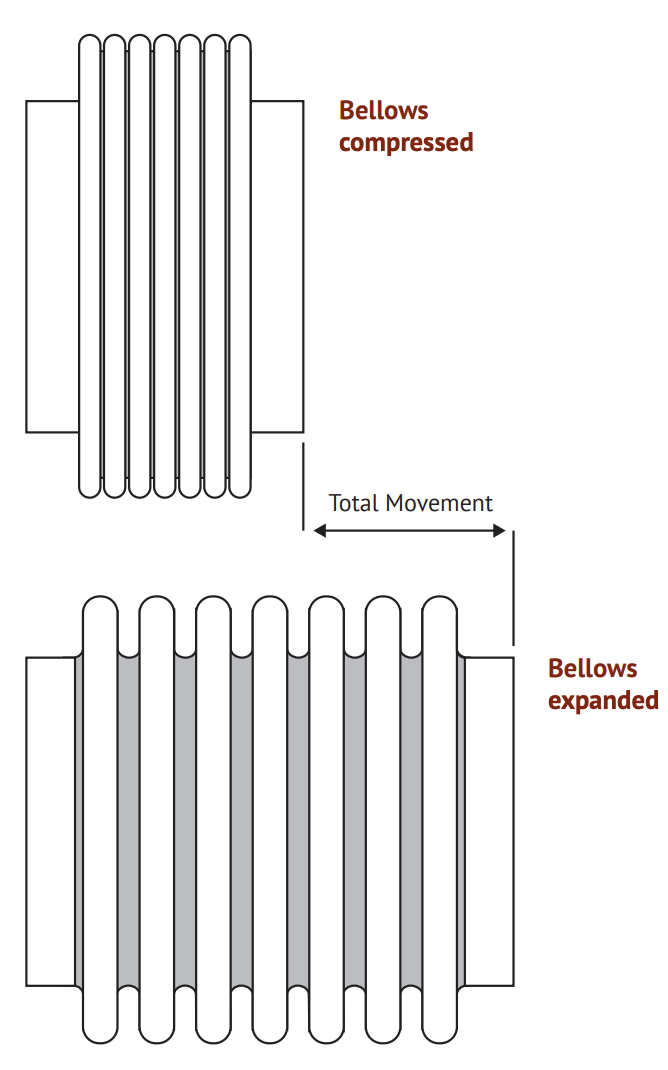

Axial Movement

Expansion joints are very good at absorbing axial movement, or the compression and extension of the bellows along a single axis. Whether the component is installed horizontally or vertically, it doesn’t matter.

This kind of movement is typically associated with thermal growth and contraction and found in piping and ducting systems across a wide range of industries.

Externally Pressurized Expansion Joints have a unique design whereby media comes into contact with the outside rather than the inside of the bellows. This external pressurization allows the components to absorb larger amounts of axial movement than more traditional expansion joint designs.

Metal hose is not designed to accommodate axial movement. When a hose is compressed axially, the braid falls out of tension and can no longer serve in its pressure carrying capacity. Once this happens, even at moderate working pressures, the hose is liable to squirm, braking through braid and resulting in a failure.

Vibration Damping

Expansion joints are sometimes a better option in applications with extreme vibration, like what you might find in exhaust systems or piping systems with pumps.

As they can accommodate movement in all directions—axially, laterally, or angularly—they can better absorb vibrations that might otherwise prompt a hose failure or cause stress on the piping system as a whole.

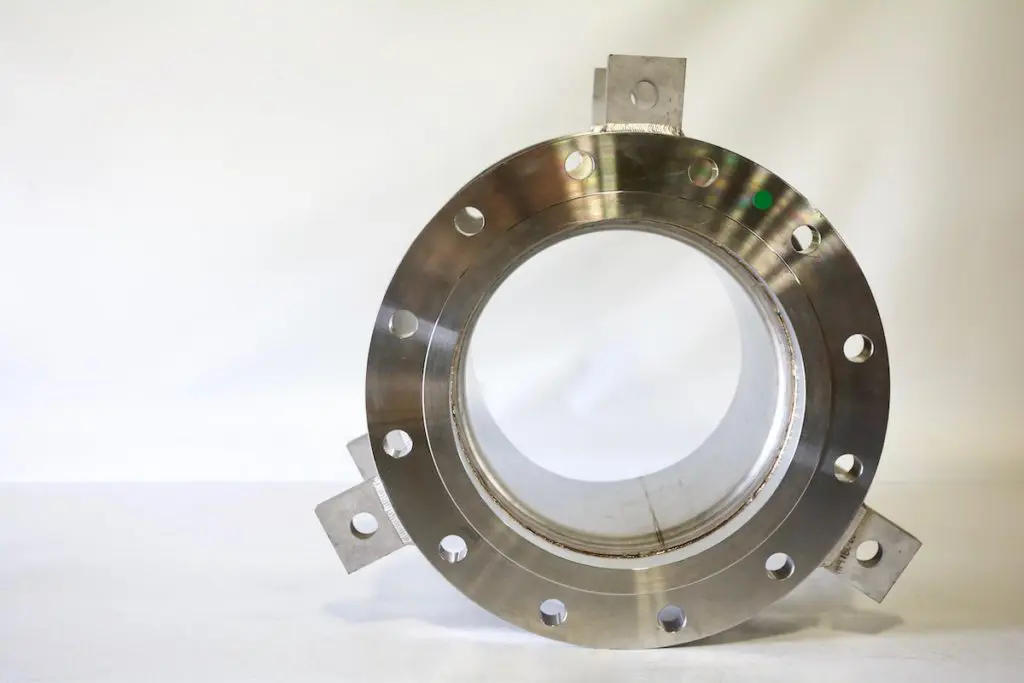

Exotic Material Requirements

Certain alloys, like 800H, Nickel 200, Titanium Grades 1 and 2 and Duplex 2205, may be desired for extremely hot or highly corrosive applications. They are, however, not readily available in a metal hose product and an expansion joint may be the only viable option in some scenarios.

Paper mills, for instance, often use titanium expansion joints to defend against the corrosion so inherent in their operations.

Space and Size Limitations

Expansion joints may be the right solution simply because they take up less space than a hose or because the diameter required lies outside the typical range of hose sizes.

It would be much easier to find a 30” expansion joint than a metal hose with a 30” ID. Penflex manufactures large bore hose up to 24” in diameter but expansion joints can be made up to 120” in diameter.

In some situations, the decision to use an expansion joint instead of a hose will be an easy one. Other times, the answer may not be so clear. Rather than deciding between an expansion joint and a metal hose, the answer may in fact be a combination of the two!

***

For information about Penflex Expansion Joints, please click here. We’ve also pulled together a 40-minute webinar that covers expansion joint basics. To watch, please click here.