Using Traveling Loops to Accommodate Axial Movement in Piping System

Hoses perform a valuable function in piping systems by absorbing movement. Rigid as they are, hard pipe and equipment can crack under the stress of movements, while hoses, being flexible, can bend without breaking.

Picture expansion joints in bridges. Or flexible foundations under buildings in earthquake prone areas. These structural elements protect immovable objects from unstoppable forces. Hoses do the same thing in piping systems.

Why Can’t Hoses Move Axially?

While braided hoses are pliable and seemingly capable of moving in many directions, they are not actually designed to accommodate all kinds of movement.

To be a pressure carrier, the hose must be a braided hose. It is the braid that prevents the hose from growing back into a tube when pressurized, and thus its strength largely determines a hose’s working pressure.

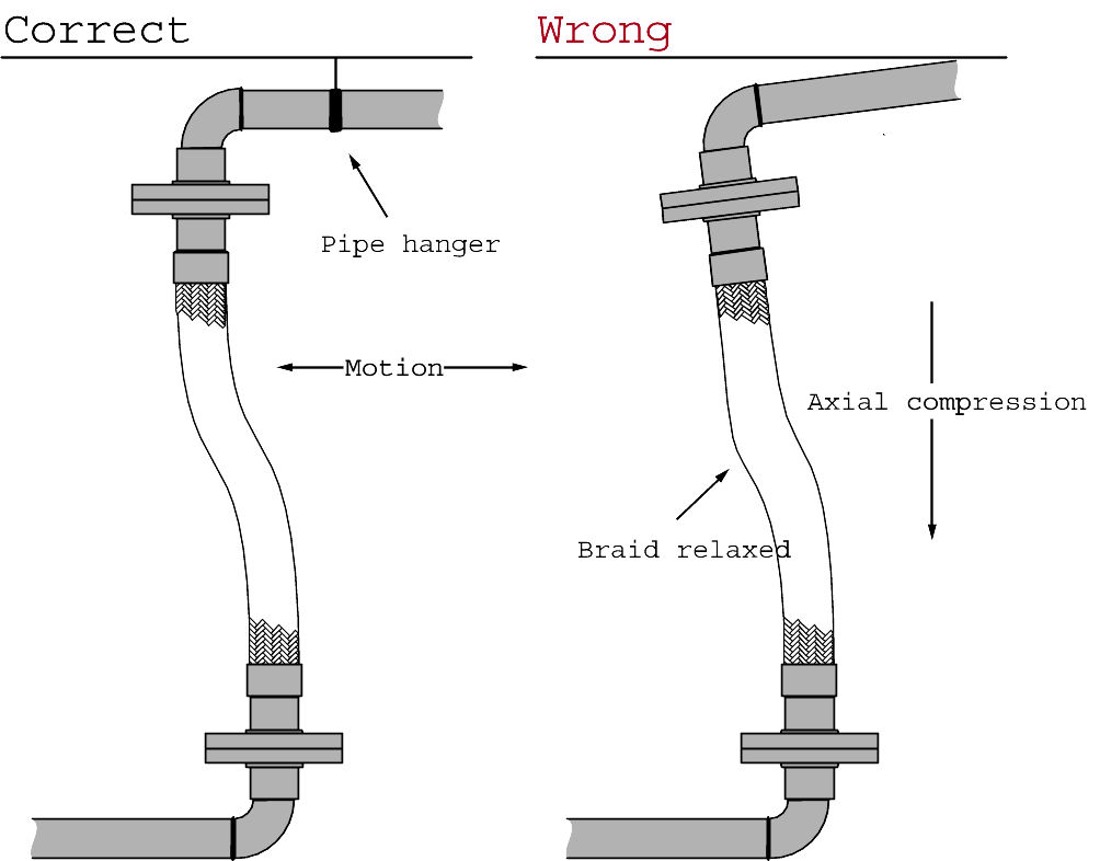

To function properly, the braid must be in tension. Compression along the longitudinal axis would bring the braid out of tension and, for this reason, hoses cannot accommodate axial movement.

Beyond a reduction in pressure carrying capacity, once a braid comes out of tension, there is a tendency for the hose to wiggle. It can exploit weaknesses in braid coverage and squirm out, leading to a sometimes dramatic-looking failure.

Though hoses themselves are not designed to move axially, they can still accommodate axial movement of the piping system.

Accommodating Axial Movement of Piping System

To accommodate axial movement within a piping system, hang hoses in traveling loop configurations. There are three broad categories of configurations. Horizontal and vertical installations are options within each one.

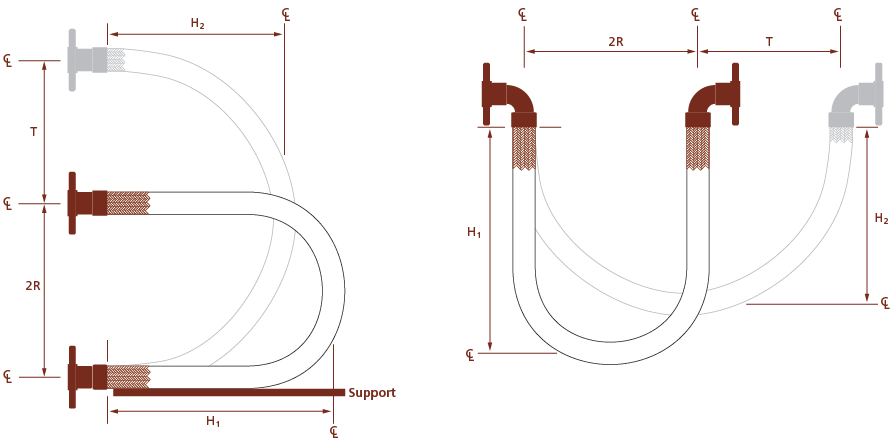

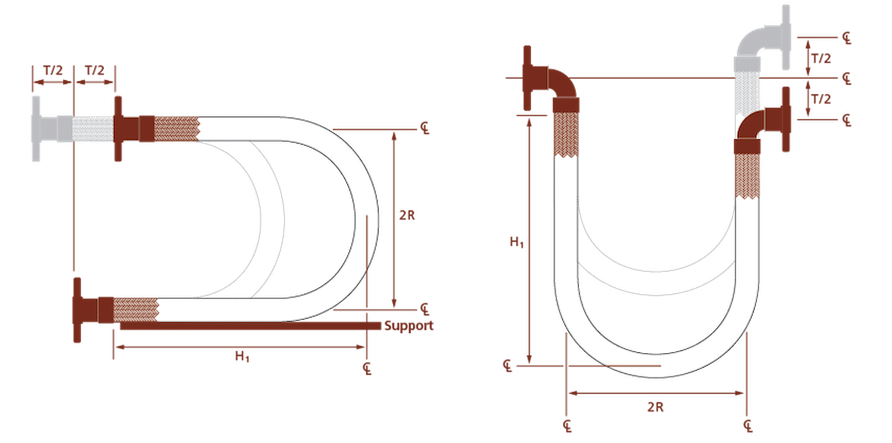

In a Variable Radius Traveling Loop, the end of the hose moves in and out in a horizontal configuration and up and down in a vertical configuration. Regardless of orientation, the radius changes throughout each cycle.

In a Constant Radius Traveling Loop, the end of the hose moves up and down in a horizontal configuration and in and out in a vertical configuration. Regardless of orientation, the radius remains constant throughout each cycle. While this installation requires more space than a variable traveling loop installation, it can accommodate more movement.

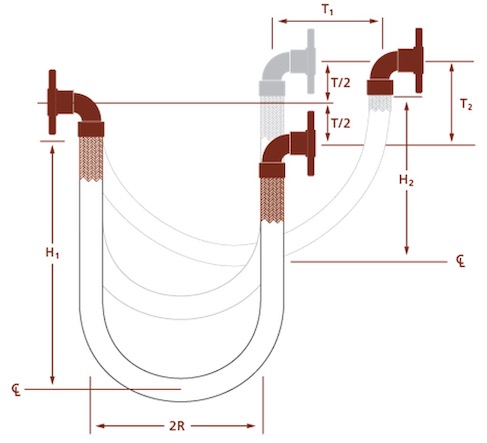

Traveling Loops with Movement in Two Directions combine the movements of Variable and Constant Radius Traveling Loop configurations. So long as the two movements do not prompt axial compression, the two movements can happen simultaneously.

When There Isn’t Enough Space

Traveling loops are an ideal configuration for hoses because the length of the installation limits stress on individual corrugations. While this ensures hoses reach maximum service life, it also makes traveling loops unsuitable in applications where there is not a lot of space.

In these scenarios, some users may opt for U-Loops and V-Loops. The returns and elbows in these assemblies save space. And while these may look like traveling loops to the untrained eye, they actually absorb movement differently. U-Loops and V-Loops use two hoses, each moving in a lateral offset motion, to accommodate the axial movements of a piping system. This can stress the end fitting connection welds more acutely though this may not be an issue in an infrequently cycling application.

Where space is especially limited, or if there is no space beneath the piping, an expansion joint may be the best design for the application.

Unplanned Axial Movement

While this bulletin focuses on how hoses can be configured in loops to accommodate axial movement in a piping system, where the design is carefully considered to avoid the hose experiencing this kind of movement, there are other scenarios where axial compression happens inadvertently.

Improper installation of hoses hung vertically can lead to axial compression of the hose. In the drawing below, you can see that without pipe support, the hose slouched and the braid relaxed. To prevent this, system owners use pipe hangers.