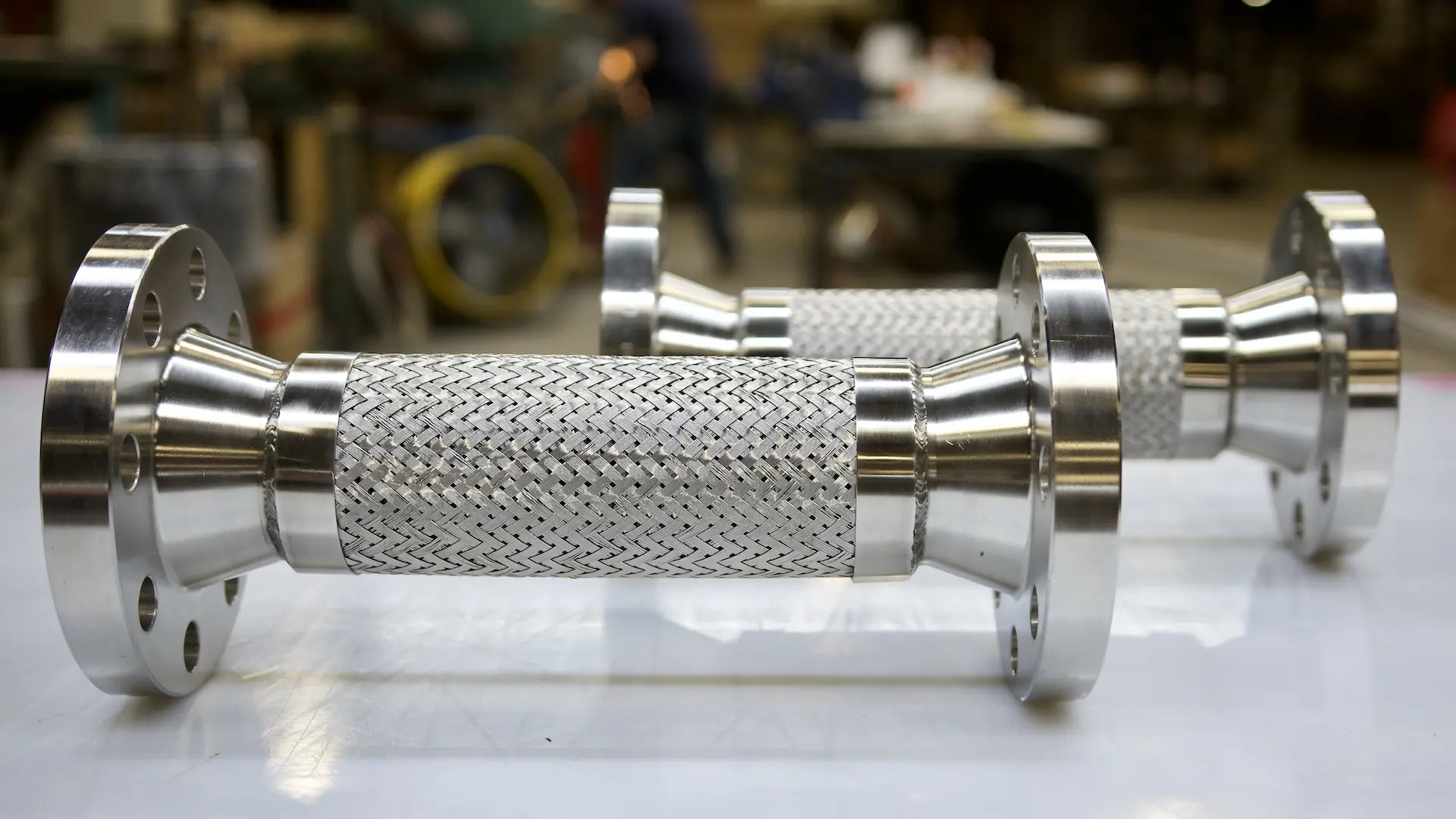

Custom Assemblies

Penflex’s team of ASME Section IX-qualified welders serve as an extension of our customers’ weld shops, most often assisting with high-volume projects. Building custom assemblies from customer-approved drawings, our welders consistently deliver high-quality components across the full range of hose sizes and alloys.

Given our familiarity with exotic alloys (and approved weld procedures), many rely on us to deliver these special assemblies. A common request is for chlorine transfer hoses, which, to be in compliance with The Chlorine Institute’s Pamphlet 6, must be made with Monel or Hastelloy.

Meet a Few Penflex Welders

Welding team leader Shane is a seasoned pro and here he is talking about all the cool things he welds aside from metal hose. Our local Texas Roadhouse is sure excited he’s around!

A newer addition to the Penflex welding team and a naturally gifted welder, Danielle Bronico tells us what it’s like to show the guys how it’s done.

ASME Section IX

Section IX of The American Society of Mechanical Engineers’ (ASME) Boiler and Pressure Vessel Code (BPVC) is considered the industry’s highest standard when it comes to welding. Our certified welders have undergone rigorous training and years of experience to deliver the superior welds that have become a trademark of our work, meaning our hoses are complete with top quality welds.

Build Your Own Assembly

Design your own assembly and generate a PDF. No CAD software needed!

Bulletin #174

Why tolerances for corrugated metal hose can’t be zero.

Minimum Live Length Calculator

Quickly determine the minimum live length requirement for your hose assembly.