Power Generation Expansion Joints

The trends surrounding renewable energies and efficient energy consumption are placing new demands on power generation facilities. Constant cycling to balance the grid puts equipment under additional thermal stress while more efficient boilers or heat exchange systems may be needed for a retrofit.

To better manage operations and maintenance costs, there can be no weak links in the system. Piping that can efficiently and effectively operate under given temperature, pressure and vibration requirements is critical to a successful operation.

With decades of engineering and manufacturing expertise in power generation applications, Penflex continues to innovate and improve its processes to keep pace with the speed of change in the industry.

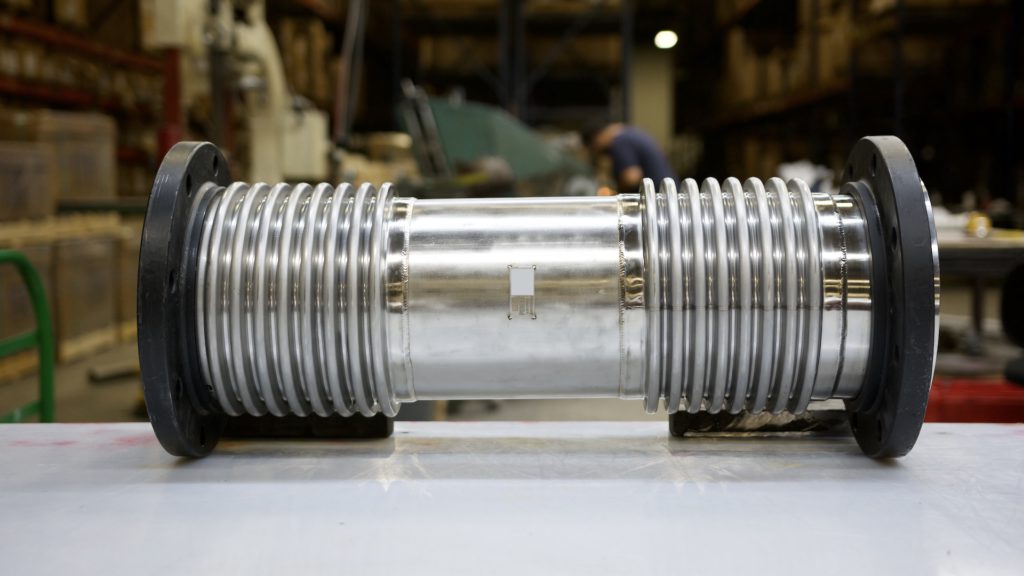

Metal Expansion Joints

Hot exhaust gases moving at high velocities and at varying pressures expose a gas turbine system to thermal stresses and considerable vibration. To accommodate the thermal expansion and irregular, consistent movement, expansion joints need to be designed for extreme operating conditions.

Penflex designs and manufactures metal expansion joints in accordance with EJMA and ASME B31.1 specifications. These are used at various turbine intersections, including at the air inlet and exhaust outlet, just beyond the diffuser, on the outlet ducting itself and in connection with the bypass stack. Boiler penetration seals and safety relief valves are just a few of the many names given to power generation expansion joints Penflex makes.

Key Features

- Single and multi-ply bellows options

- Pipe sizes of 2.5” and up

- Various attachments are available

- Options for Universal Joints

- Non-Destructive Examination is available

Bulletin #160

How to install an expansion joint.

Expansion Joint Catalog

Overview of Penflex’s full expansion joint and raw bellows offerings.

Bulletin #152

When to use an expansion joint instead of a hose.