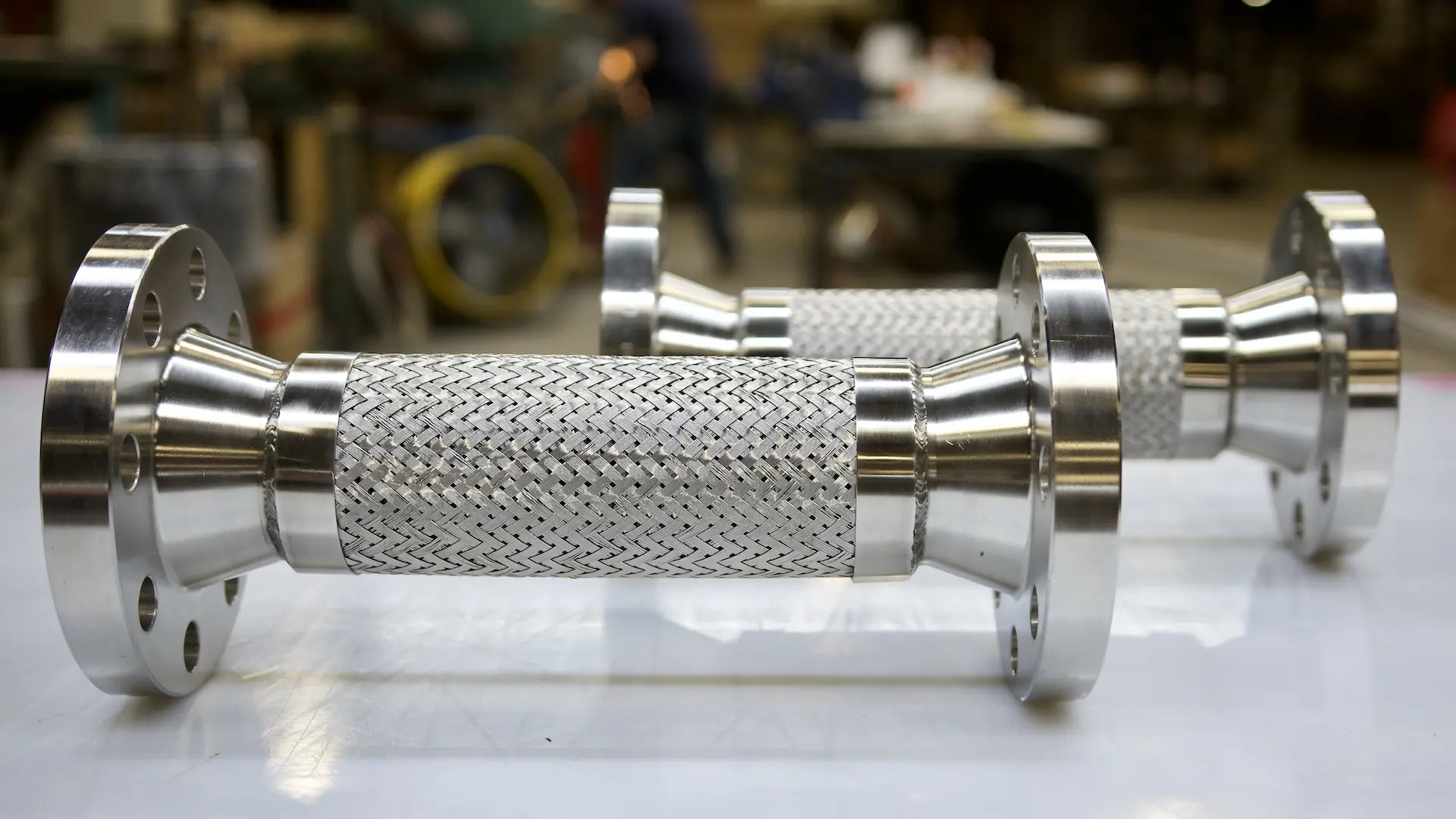

625 Inconel

625 series hose and braid is made with Inconel 625, a superalloy with excellent corrosion resistance and high temperature properties. Whereas the maximum service temperature for the 300 series stainless steels is 1500°F – ideally 1000°F for non H-Grade alloys–the maximum for Inconel 625 is 1800°F!

Given the 300 series stainless steels are notoriously sensitive to chlorides and pitting corrosion, Inconel 625 can be a better design choice in applications involving such aggressive media. Just consider the fact that Inconel 625 has a PREN more than double the PREN of 316L, 46.4 – 56.0 versus 22.6 – 27.9. The higher the PREN, the more successfully an alloy will resist pitting corrosion, and subsequent failure.

Benefits

- Excellent corrosion resistance

- Superior high temperature properties

- Good pressure ratings

Technical Specifications

- Construction: Annular hose with a standard pitch

- Hose material: Inconel™ 625

- Braid material: Inconel™ 625

- Hose sizes: 1/4″ through 8″