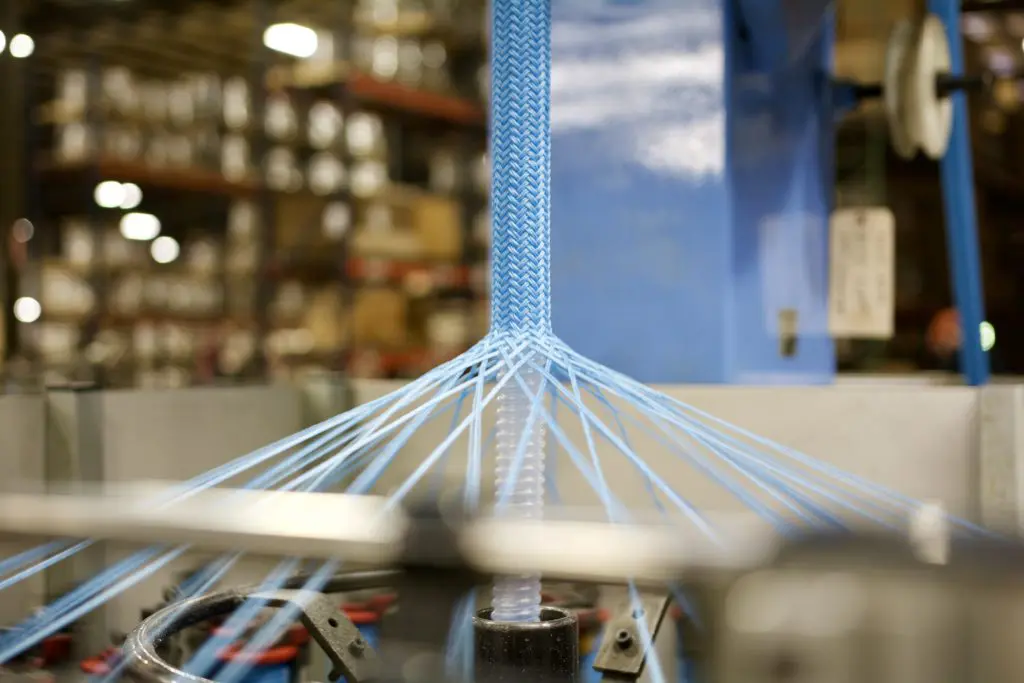

Braiding For Hoses

Braiding for hoses plays a critical role in almost every hose assembly—it’s the pressure carrier! Without it, under pressure, a hose will elongate, and try to turn back into a tube. In addition to this role, braid can also protect the inner core from damage due to abrasion and general mishandling. Often, metal hoses are double braided to make them more robust in handling as much as they are for increased pressure capabilities.

Penflex offers specialized braiding services across a wide range of hose sizes, braid configurations and braid materials. While we braid standard or customized metal hoses, we also braid customer-supplied hoses with a wide variety of metallic and synthetic wires or threads.

We can even braid without a hose or liner in long continuous lengths, up to a few thousand feet!

Alloy Examples

- 304L

- 309L

- 316L

- Monel 400

- Inconel 625 and 718

- Hastelloy C276

- Titanium

Non-Metal Wire Examples

- Polypropylene

- Kynar ™

- Kevlar ™

- Polyethylene

- Other threads

Customer-Supplied Hose Examples

- PTFE Hose, smooth bore and convoluted

- Rubber Hose

- Hydraulic Hose

- EPDM Hose

- Cables

- Wiring Bundles

Braid Construction

Braid construction describes how the braid is made. For example, when looking at 36 x 9 x .016:

- 36 = number of carriers

- 9 = number of wires on each carrier

- .016 = diameter of wire in inches

With our large fleet of braiders ranging in size from 24 to 96 carriers we can offer many options and solutions. Change the variables for braid construction–listed here–and you can change pressure carrying capacity and braid coverage within material and machine limits.

- Number of carriers

- Number of wires per carrier or band

- Wire diameter

- Wire tensile

- Braid angle

With many years of experience, we can help you come up with a design to meet your needs!