Chloride/Chlorine Levels and Stainless Steel Alloy Selection

Note: To print this bulletin on chloride/chlorine levels and stainless steel alloy selection, please click here.

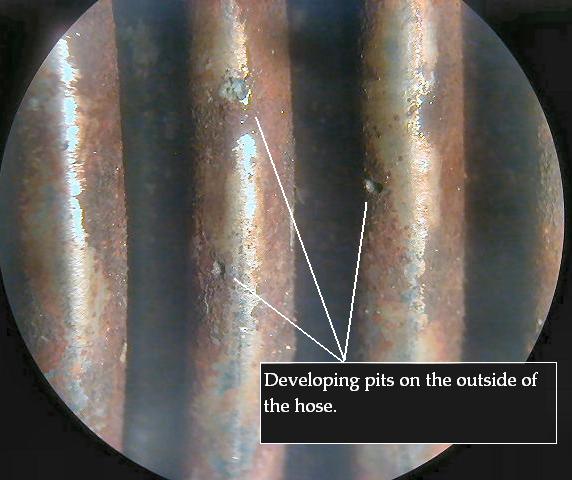

Pitting corrosion occurs when chloride levels exceed recommended levels.

The 304 and 304L (18-8 stainless steel alloys) have been utilized very successfully in fresh waters containing low levels of chloride ion of up to 100 ppm. This level of chloride is considered to be the limit for the 18-8 alloys, particularly if crevices are present. Higher levels of chloride might cause crevice corrosion and pitting. The 18-8 alloys are not recommended for exposure to marine environments which have much higher levels of chloride.

The resistance of the stabilized Alloys 321 to pitting and crevice corrosion in the presence of chloride ion is similar to that of Alloy 304 or 304L stainless steels because of similar chromium content. And therefore 100 ppm chloride in aqueous environments is considered to be the limit for the stabilized alloys, particularly if crevices are present.

For more severe conditions of higher chloride level, lower pH and/or higher temperatures, alloys with Mo (molybdenum), such as Alloy 316, should be considered. The Mo-bearing Alloy 316 and Alloy 316L may handle waters with up to about 2000 ppm of chloride.

Another factor to consider is the amount of free Chlorine (Cl2) (usually derived from sodium hypochlorite) which is added to water (well water, drinking water, swimming pool water, etc.) to kill bacteria. Cl2 (chlorine) is a very potent oxidizer (reason it kills bacteria) and therefore high levels of Chlorine may accelerate chloride corrosion of stainless steels. 304 and 304L, 321 SS may be used for “water applications” with up to 2 ppm chlorine, while 316 and 316L alloys may “take” up to 4 ppm.

If looking for information about Chlorine Transfer Hoses, please click here.

If you have any questions or comments, please contact us.

Disclaimer: The info presented here has been compiled from sources believed to be reliable. No guarantee is implied or expressly stated here and the data given is intended as a guide only.

To print, please click here.