An Overview of Common Expansion Joint Accessories

Accessories are added to an expansion joint installation to meet specific customer, application or code requirements. Some are used to control movement, others to protect the bellows in the event of pressure thrust, and still others to defend against corrosion caused by media inside or from the environment outside the bellows.

Here is an overview of the most common expansion joint accessories.

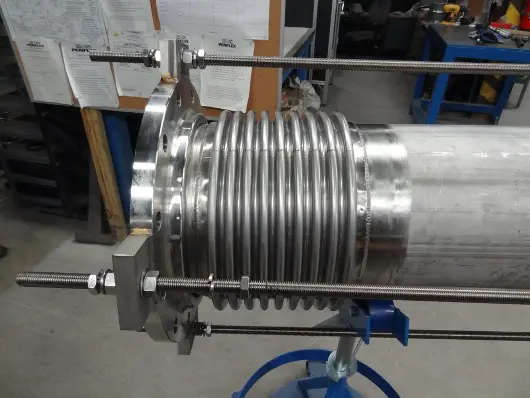

Limit Rods

The primary function of limit rods, sometimes called limit bars, is to restrict the range of movement—whether that be axial, lateral or angular—during normal operations, thereby preventing premature failure. Nut stops placed along the rods determine just how much extension and compression an expansion joint will accommodate.

The Expansion Joint Manufacturers Association (EJMA) standards state that “in the event of a main anchor failure, limit rods are designed to prevent bellows over-extension or over-compression while restraining the full pressure loading and dynamic forces generated by the anchor failure.”

The number of limit rods is calculated based on the pressure thrust that needs to be contained. EJMA recommends a minimum of three rods.

Tie Rods

Tie rods are similar to limit rods, though they cannot accommodate axial movement. Limit rods can. The sole function of tie rods is to continuously restrain the full bellows pressure thrust in normal operation while allowing only for lateral deflection.

If only using two tie rods—and placing those two rods 90 degrees from the direction of rotation—you could accommodate angular rotation. This could be a cost-effective alternative to a hinged expansion joint.

Control Rods

Control rods are commonly confused with limit and tie rods, but it’s important to understand precisely what is specified as the accessories serve different functions.

These accessories are only used in universal expansion joints to distribute movement between the two bellows. Unlike limit and tie rods, they are not designed to carry the pressure thrust in any circumstance.

Shrouds

Also called covers or guards, shrouds encase the bellows, protecting it from external damage and external flow. Sometimes, a shroud will be needed just during installation to, say, protect the expansion joint from getting hit with a hammer. Other times, the shroud will be needed throughout operation.

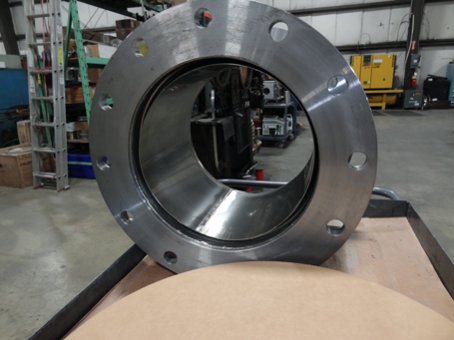

Liners

Liners, also called sleeves, are metal devices installed on the inside of a bellows to prevent flow-induced vibration which leads to stress cracking and failure. All Penflex bellows and expansion joints are designed in accordance with the allowable values specified in the latest EJMA standards. These let us know how thick liners need to be to prevent flow-induced vibration.

Liners also prevent the build-up of material on the inside of the bellows. This would be a consideration when working with some media, like concrete for example, that hardens below a certain temperature. Shielding the inside of the bellows also protects them from caustic media.

Together with shrouds, liners are the most commonly specified accessories we see.

***

For information about Penflex Expansion Joints, please click here. We’ve also pulled together a 40-minute webinar that covers expansion joint basics. Take a look!