Company History and Facts

1902: Penflex is founded.

1906: Penflex becomes the first manufacturer in America to produce flexible interlocked metal hose.

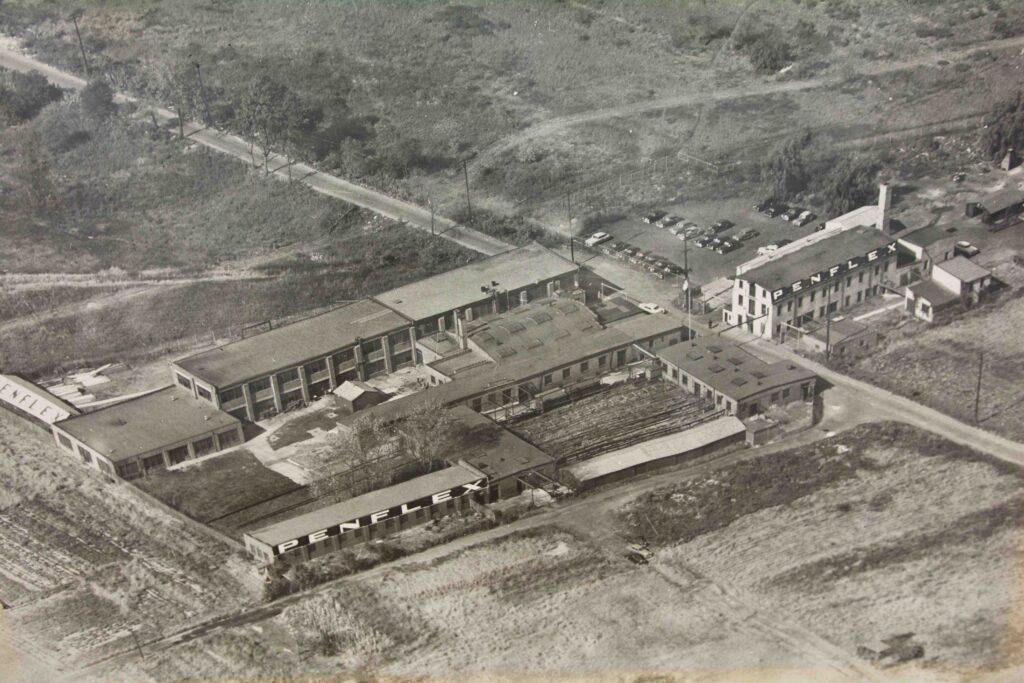

In the 1930s, Penflex was located on South Broad Street near the Philadelphia Navy Yard, about 50 miles from Penflex headquarters today in Gilbertsville, PA.

1939-1944: During World War II, Penflex, responding to a high demand, started to produce Galvanized Steel hose that was widely used because of its fire-resistant quality and electrostatic protection. The Interlocked hose made of Galvanized Steel was used at Gulf port terminals to unload oil from oil tankers, and on open hearth furnace at several plants of leading steel manufacturers.

Late 1990s: Penflex introduces several new series of products, including a light weight series 500 hose and the series 600 hose with extreme flexibility.

Mid 1990s to 2000: Penflex Corporation doubles capacity, due to a series of manufacturing improvements.

2001: Penflex introduces the series 900 high pressure hose.

2005: In order to meet future growth, the Company moves to a new 100,000 sq. ft. manufacturing facility in Gilbertsville, PA.

2006: Penflex introduces a new, larger heavy-wall hose with OD up to 14.

2008: Penflex implements semi-automated Leak Detector line able to catch leaks as low as 0.0000005 [1×10-5 cc/sec], practically eliminating “leaking hose” issues.

2009: Penflex introduces new product line, the P3 series corrugated hose. These new products are supplied with a higher coverage braid which is designed to sustain the highest available working pressures and provide maximum protection of integrity to the inner core.

2010: Penflex opens new warehouse and production facility in Asia.

2010: P3 Hose products are certified to the International ISO 10380 Standard as a Type 1 hose allowing Penflex to introduce these products to a broader customer base on the European continent.

2013: Penflex introduces P4, the newest generation of Penflex Annular Corrugated Metal Hose products which provide high uniformity of corrugations and consistency of the pitch. The full coverage braid of P4 products is designed to sustain high working pressures & provide maximum protection to the inner core.

2014: Penflex expands product line to include expansion joints.

2016: The company establishes the Welder Training Program onsite at company headquarters to better support customers in the application and use of Penflex products.

2017: Penflex expands product line further to include fittings to better support key customers.

2018: Penflex acquires 96 carrier braid machine to bring production of 6″ – 12″ braid in-house.

2020: Penflex opens its own warehouse in Houston, TX to better serve customers along the Gulf Coast.